Sponsored Content: Young Innovations

How an education-based shift helped triple production

By Amanda Hill, RDH

Fluoride varnish treatment is an established standard of care, but many group practices routinely leave valuable varnish production on the bracket tray, or even in the supply closet. This not only affects a DSO’s bottom line, it’s a missed opportunity to provide a thorough prevention-focused visit, elevating the clinician from a teeth-cleaner to a healthcare provider.

One company is helping DSOs increase their varnish production through a unique program that goes beyond the usual “price-and-product” approach of other manufacturers. In this case study, we’ll explore how Sage Dental increased fluoride varnish production by more than 200% through a relatively simple method: clinical education.

Varnish Hurdles

Fluoride treatments are an exceptional service for preventing tooth decay. Since the 1940s, they’ve been shown to be safe and effective in preventing tooth decay for both children and adults, alike.

According to the American Dental Association (ADA), 2.26% fluoride varnish (5% sodium fluoride) or 1.23% APF gel is the standard of care in professional fluoride treatment. However, patients have a low dental IQ or even fear around fluoride. Clinicians are also unsure of how to increase case acceptance without feeling pushy or like they are “selling” treatment.

Fluoride treatment costs vary from $25-$35 per application, and depending on caries risk assessment, patients may or may not be reimbursed by private insurance, leaving yet another hurdle to treatment acceptance.

Why Varnish?

Commonly, DSOs look to price and efficiency when choosing products. Fluoride varnish is the perfect balance of cost and production. It’s quick and easy to apply, readily tolerated by patients of all ages, and priced reasonably enough to keep the shelves stocked.

Unlike the old goopy tray method or rinses, fluoride varnishes adhere to the tooth, allowing for longer exposure time. They have proven to effectively reduce caries and help seal dentinal tubules, aiding in the relief of dentin hypersensitivity (DHS). One added bonus is that patients can feel varnish, giving them a better connection to what they are paying for.

When you’ve already implemented as many cost-saving measures as possible, where do you go next to boost your production? One company flipped the script and took an education-based approach. They shifted their mindset to seeing each patient as a new patient with individual needs. By doing so, they created an effective playbook for increasing varnish production by more than 200%.

A New Approach

Young Innovations helped Sage Dental identify an opportunity to increase fluoride varnish applications by educating clinicians. Prior to the program, Sage Dental was doing $38,000 in fluoride varnish production per month. Production had stagnated after all traditional growth avenues had been exhausted. Varnish was expiring on the shelves because clinicians didn’t have a product they believed in, made time for, or understood.

Sage Dental partnered with Young Innovations to implement a fluoride varnish production program. Young Innovations has been a leading dental manufacturer since 1900 and is known for its prophy angles, among many other quality preventive products.

Soaring Production

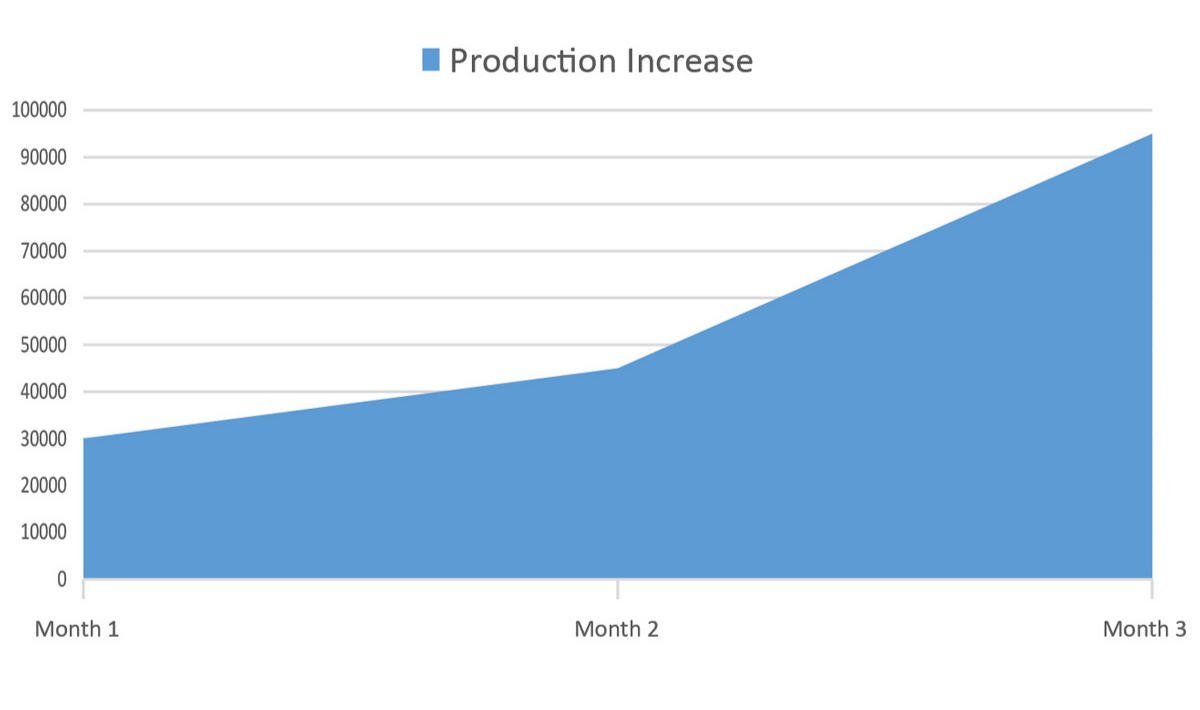

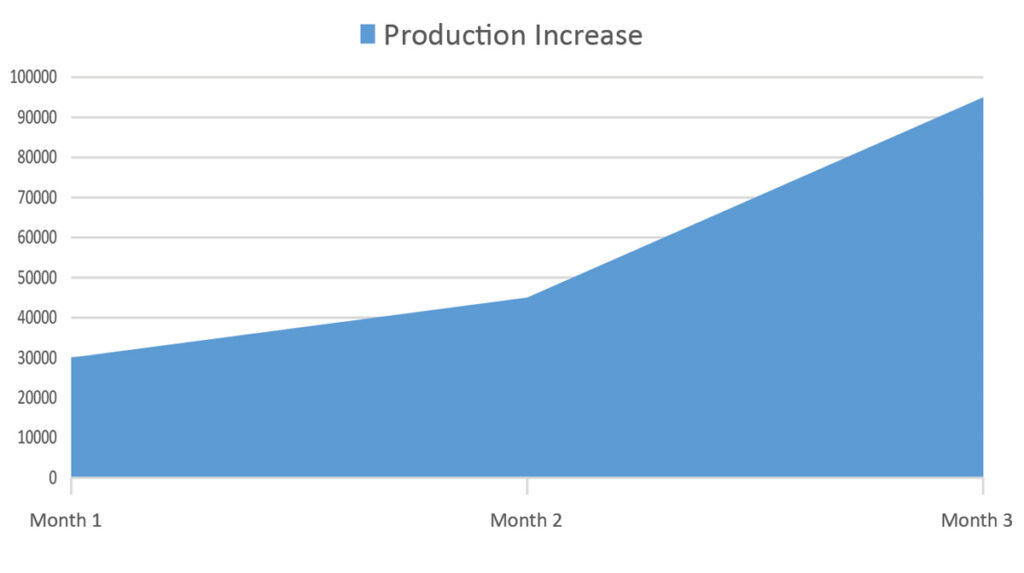

Sage Dental saw its monthly fluoride production increase by over 200% after implementing the program in partnership with Young Innovations. In month one, they saw an increase of $30,000 in fluoride varnish production. In month two, it jumped to $45,000, and by month three, it exploded to $95,000.

In just three months, production tripled!

“We have an amazing partnership with Young Innovations. We switched to Young’s varnish and we saw a 75% improvement in utilization and acceptance,” said Misty Mattingly, Vice President of Hygiene Operations at Sage Dental. “The hygienists loved the product, which made them more apt to recommend it.”

“By finding a product that our hygienists liked, understood, and believed in, we were able to shift their mindset from selling a product to patients to providing a product or procedure that benefited their patient, based on the individual needs,” Mattingly said.

The Secret Formula

Let’s take a look at a hypothetical example: Practice A has 100 hygienists, with three hygienist workdays per week, seeing about eight patients per day. Approximately 50% of their patients receive fluoride varnish treatments that each cost $35. With Young’s fluoride varnish program, this practice can grow its varnish production an additional $42,000 per week, which adds up to $2,167,200 per year.

Partnership Success

What makes this approach successful? Young Innovations offers a partnership that goes well beyond products and pricing. Young Clinical Representatives (YCRs) – a team of over 100 registered dental hygienists located across the United States – are trained to coach other clinicians on fluoride acceptance. Presenting their comprehensive continuing education course, How to Take the NO Out of Varnish Recommendations, local YCRs work directly with DSO hygiene teams to build clarity and confidence around fluoride varnish advocacy.

When hygienists genuinely understand the why behind varnish and how to customize their recommendations to the unique needs of the patient, it goes from selling a product to providing a preventive service to a patient they care for. It no longer feels like one more task to add to an already over-packed hygiene appointment. YCRs recognize clinicians’ stumbling blocks and set them up for success. And that leads to treatment acceptance and better outcomes.

Driven by Results

An education-based program is a proven approach to increasing fluoride varnish production. When clinicians are given the opportunity to truly understand a procedure and move from the feeling of selling a product to feeling empowered in their role as a healthcare provider, they begin to seek out ways to improve patient outcomes. Through improved communication skills and understanding, hygienists can connect with patients on how fluoride varnish is the ideal preventive treatment for them.

Young Innovations is uniquely positioned to support fluoride varnish integration in DSO spaces. With more than 100 trained clinical representatives to support clinicians in group practices across the country, the program is scalable to fit any size DSO.

When Young Innovations presented this program, Sage Dental saw the opportunity to educate and empower their clinicians. By implementing this production-boosting program, Sage Dental was able to more than triple their fluoride varnish production and elevate their hygienists into the role of healthcare provider.

“Fluoride was just the beginning,” Mattingly said. “We are using this same approach with other initiatives and have created similar success.”

Visit youngspecialties.com/dso for more information about how you can implement this program in your group practice.