Sponsored Content: National Dentex Labs

Benefits for clinicians, labs, and patients.

BY Jamie Stover, CDT, Senior Manager Of Dental Lab Applications, Carbon, National Dentex Labs

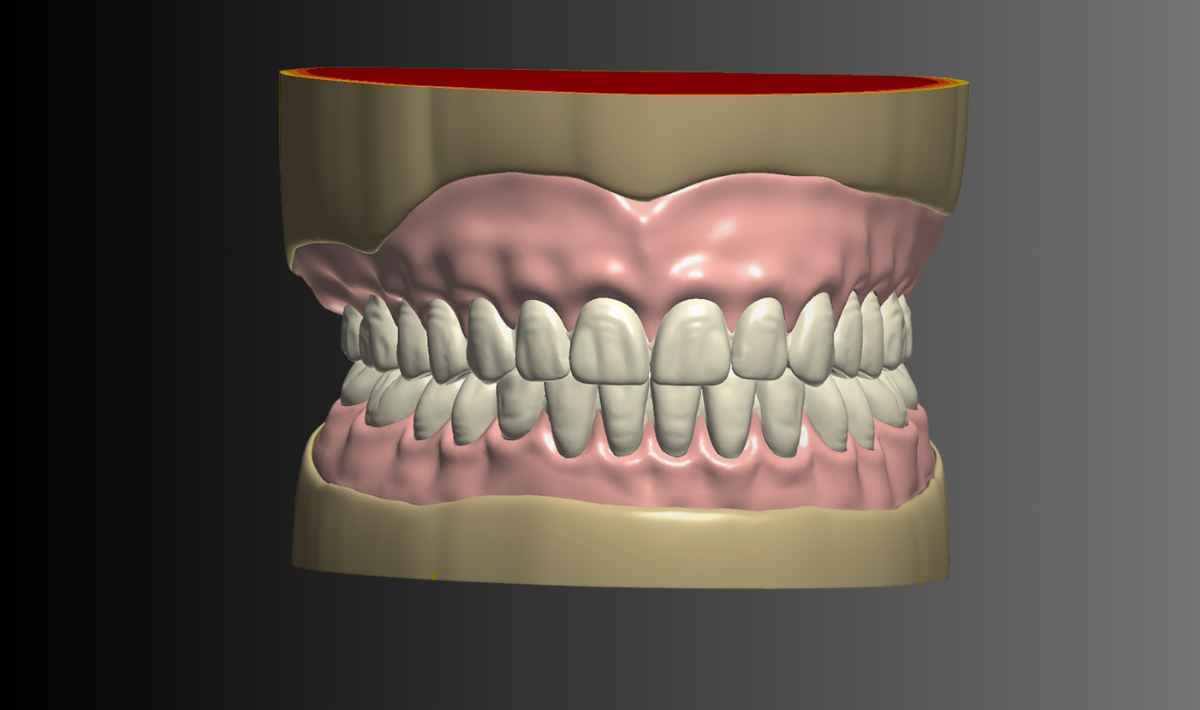

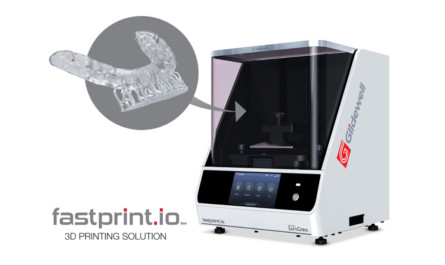

Additive (3D printing) manufacturing processes have become commonplace in the dental industry due to improvements in CAD/CAM software and hardware, and the development of exciting new materials for many dental applications. 3D printed dentures are one such application that provides many benefits at a critical time, as our industry faces a growing edentulous patient base. 3D printed denture fabrication allows labs to transition the experienced removable technicians out of analog roles at the bench and into roles as digital denture designers, digital clinical/technical consultants, and educators and trainers. National Dentex Labs is leading this digital transition with NDX Digital Dentures.

The Three Appointment Workflow

Clinicians utilizing intraoral scanners can reduce the number of clinical appointments required to deliver the final denture from the standard 4 or 5 appointments with the traditional acrylic denture workflow to as few as 2 or 3 appointments with what is commonly referred to as the copy and reference denture workflow. This involves scanning a patient’s existing denture and sending the IOS file to the lab where it is imported into denture design software for fabrication. If the fit of the patient’s existing denture to the tissue is poor, a wash impression can be taken with their denture in place before scanning and sending the file to the lab. After those steps, the impression material is removed, and the denture is returned to the patient to wear while the new denture is fabricated. Copying a patient’s existing denture without changing tooth position, shape or occlusion means the clinician can skip the try-in and deliver the new denture with only two clinical appointments. If changes to the existing denture are required and a try-in is requested, the final denture can be delivered with three clinical appointments.

A Digital Record

Another benefit of 3D printed dentures is that the digital record can be stored by the lab so that in the event a denture is lost or needs to be replaced for any reason, it is not necessary to start over with a new impression and bite records. Instead, the lab accesses the design file, re-prints and finishes a new denture and delivers it. If the bone and tissue position change between the time the original and replacement dentures are fabricated, the lab can re-print the monolithic try-in and the dentist can take a wash impression with the try-in placed in the mouth. The lab then scans the try-in, combines the new data with the existing denture file, and re-prints/finishes a new denture that fits the tissue accurately.

The Digital evolution of our industry continues to provide exciting new ways for clinicians and dental lab technicians to collaborate efficiently. NDX Digital Dentures is an excellent example of a powerful new application with impactful benefits for clinicians, labs and patients.

Jamie Stover, CDT is the Senior Manager of Dental Lab Applications at Carbon and has been a dental laboratory technician for over 24 years. In his role, Jamie oversees application support globally for dental materials. As a consultant for labs and clinicians, he helps to streamline production with the digital workflow and implement strategies for business growth/development and utilization of new applications.