By Dr. Sami Bahri, DDS

Three keys for leaders to change behavior

Success depends on more than a single factor. Successful leaders, however, manage to simplify their work to just a few important factors.

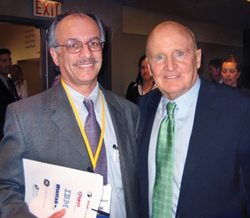

As part of a small group of speakers at a healthcare summit in Orlando, Fla., I was offered the incredible opportunity to spend an hour with Jack Welch, the former CEO of General Electric.

I’ll try to summarize his advice in my own words: You determine a few key behaviors expected from your employees, and you base everything – promotion, bonus, dismissal, etc. – on their alignment with those behaviors.

To apply his advice, we all teamed up and identified those key behaviors. But, to change our own behavior accordingly was not easy; we needed time and effort. I wanted to make it easier by creating conditions that encourage behavior alignment, but to my frustration, I didn’t know how to go about it.

Our hope for a practical solution came from a statement by Fujio Cho, Chairman of Toyota: “Go see, ask why, show respect.” This short statement condenses many decades of “trial and error” in leadership and human relations. Notice the action verbs; he’s not explaining theory, but real-life leadership in action.

To put his statement in context, it would help to explore the most common models of leadership dominating today’s workplace:

Older “command and control, dictator” style.

“Do it my way.” A dictator tells people what to do, how and when to do it. All the thinking is limited to the leader, which causes this authoritative style to miss one of the most important factors in increasing productivity, human participation, and human creativity.

Newer “excessive empowerment” style.

“Do it your way.” In this style, leaders give up their responsibilities. By leaving people unmonitored, every employee might develop in a different direction – no matter how hard they work, they neutralize each other’s efforts and restrain progress.

Lean style.

“Follow me, we’ll figure this out together.” This is our style of choice, where leaders act as coaches. They know that the future is unpredictable and face it with flexibility, by working closely with the team. All the group members become vigorous learners, helping each other to understand business systems so they can improve them.

Putting theory in practice

Chairman Fujio Cho’s statement has elegantly summarized how leaders need to change their own behavior before they can influence the behavior of others. John Shook, chairman and CEO of the Lean Enterprise Institute wrote:

“‘Go see, ask why, show respect’ is the way we turn the philosophy of scientific empiricism into actual behavior. We go observe what is really happening ([W]here the work takes place), while showing respect to the people involved, especially the people who do the real value-creating work of the business.”

When we apply this principle, we aim not only at solving problems, but mainly at building teams that can see problems as soon as they happen, and improve them immediately.

Go see

What I like about this concept is that it is consistent with how we practice dentistry. For example, when a patient calls the office with a toothache, we would certainly not treat them over the phone. We want to see the tooth, collect data about it, diagnose, prescribe and carry out a treatment, and follow it up until we know it was successful. With the “Go see” principle, we treat management processes the same way we treat that toothache.

“Go see” for problem solving.

Imagine an employee reporting a problem. Before I learned this principle, I tended to recommend solutions from afar. This often led to ineffective solutions and to employee resistance to change, because from afar, I could rarely have a complete picture of the problem. With the “Go see” principle, I go to the place where the problem is happening and grasp the situation, before moving to the solution phase. This made our solutions more sustainable.

“Go see” for continuous improvement.

You don’t need to wait for a problem to happen before you “Go see”; you can actually use it to improve any process, even those that seems to function properly.

An often-told story about Taiichi Ohno, the engineer credited with creating the lean philosophy, is that when new managers would come to Toyota, he would draw a circle on the ground near the work process. He would then ask the new manager to stand in the circle and watch. Hours later, he would return and ask the manager to describe what he saw. Inevitably, the manager would not be able to describe the wastes and problems in the process in any detail. Although the manager had been standing at the process and looking, he had not learned to “see” yet.

Ohno would not let the manager leave the circle until he could give a vivid description of what he saw, including all the wastes that could be improved upon.

Similarly, in our dental practices, we should observe processes until we are able to see and bridge the gap between how the process is functioning and how it should be functioning. The “Go see” concept can go even deeper, it can help you build a coherent team, as the following example from our practice shows.

“Go see” to build understanding and collaboration among team members:

To control the flow of treatment, we have created a simple, yet very powerful system. We simply printed a card for every step in an appointment, describing its key points. Although the function of those cards is important, in this example, we are interested in the way “Go see” has started an atmosphere of collaboration among team members while building their content.

One of the cards – a reminder to have patients review their personal information – captures information changes to prevent problems. We all collaborated in creating its content.

To begin the “Go see” process, I asked one assistant to show us how she goes to the patient information screen on her computer. She went through five or six screens, many mouse clicks, and she needed to type the patient’s name once. A second assistant used three screens and needed to type the patient’s name once; a third, two clicks with no name typing.

At this point, it would have been easy to fall in the trap of judging the first assistant as not knowing what she was doing. But when we asked her why she did it the long way, we found that she was working around a weakness in the dental management software, and that spending more efforts upfront was saving her time, overall. After further discussion, the group found a shorter way to bypass the software weakness, and still get much closer to the two-click performance.

All assistants changed their behavior immediately to match the new standard. This new way will save time, to be sure, but most important is not only the collective learning that came from that experience, but the speed at which employees improved their behavior – if you are a manager, you probably know how important that is.

Ask why

It is not unusual for two dentists to differ on how to treat the same mouth. Similarly, if two managers watch us work, based on their knowledge and experience, they would see two different realities.

The good news is that we can all learn to see deeper into the process if we ask why things are done the way they are done. In fact, we should ask why several times successively. Every answer will reveal a deeper layer of understanding and will lead us to ask the next why, until we reach the root cause of a problem or a reason to improve a process. Here is a real-life example of asking why successively (four times in this case) to solve a scheduling problem:

Dentist: “Why (1) is the periodontal maintenance patient scheduled for a regular cleaning? (Comment: Here, one could jump to blaming the scheduling person.)

Scheduling Manager: “Because in the patient history the last visit was a regular cleaning. We thought that the next visit will be similar.” (Comment: Here we start seeing that she is not at fault since the software does not provide the information in the right location.)

Dentist: “Why (2) does the last visit show a regular cleaning instead of periodontal maintenance?” (Comment: Here we start investigating the management system instead of the person who made the appointment; our goal is to find a solution at the system level, not to blame a person.)

Hygienist: “I write what patients need in the treatment notes and that does not show in the history.” (This shows the weakness in the software that does not transfer automatically the necessary information from the patient notes to the treatment history.)

Dentist: “Why (3) does the front desk not read the notes before making an appointment?” (Deeper system investigation, as one would investigate a crime.)

Scheduling manager: “Because it is time consuming; we do not have the time to look in the notes.” (Again, the software should give us the option to post that information automatically in the history screen)

Second Dentist: “Why (4) can’t we write it in a place that shows in the history?” (Now that we know the real problem, we started proposing a solution.)

Assistant: “I know a place in the software where we can do it.” (That was probably the best solution under the current conditions, since we cannot change the management software quickly.)

The assistant showed us how to do it; everyone changed immediately to the new way, and eliminated that category of scheduling mistakes immediately. Notice that the solution was created by the collaboration of all team members, with the dentist acting as a coach, not dictating any solutions.

We can train ourselves to see deeper by asking why successively in any management area. It is true that two managers with different levels of expertise see different pictures of the same practice, but the new manager can learn how to see waste and opportunities for improvement in many areas of the practice:

- We can learn to see if the work conforms to the mission and vision of the practice. For example, if an emergency patient walks in unexpectedly, and our policy says to always accommodate patients, would it be in alignment with our mission or vision to refuse seeing that patient because they don’t have an appointment?

- We can learn to see waste. In previous articles, we have exposed the seven deadly wastes in operations. It would be very beneficial if you could train your eyes and your mind to see those seven wastes so you can find ways to eliminate them.

- We can learn to see flow. Uninterrupted treatment flow is one of the most important boosters in productivity, quality, morale and patient satisfaction. At the same time, it reduces cost and mistakes. We need to see obstacles to flow so we can eliminate them quickly and permanently.

- We can learn to see problems. Anything that stops us from reaching our objectives can be a problem; we need to learn how to see those problems immediately and eliminate their causes so they won’t recur.

- We can learn to see opportunities for improvement. Operations might seem to be running efficiently but any operation can be improved.

Go to where the work is produced

Now that you know what you need to “Go see,” you might be wondering where you are supposed to go so you can see. The answer is simple, where the work is produced – around the operatory, around the sterilization area, around the front desk or around lab.

That is where we are supposed to be all the time. We are supposed to be observing how our team members perform their jobs, to be analyzing how we could remove non-value added work and how to transform it into value-added work that patients appreciate.

In my personal experience and observing my colleagues when we don’t have a patient, often times we rush to our private office and sit at the computer. In the meantime, the work area is left unattended, and the opportunity for improvement lost.

That is why I say that the doctor’s office can be a big obstacle to productivity. In fact, staying on the work floor is so important that many CEOs are reported to have eliminated the personal office altogether, and to spend all their time among workers. We need to leave our office, and “Go see” what is happening on the treatment floor, the same way we ask to see a patient when they have a dental problem.

Show respect

I truly believe that if my employees do not respect what I stand for, they would not stay with me. Similarly, if I do not have a genuine respect for their character, I would not want them to stay. Consequently, working together means that we do have that basic respect for each other, and we ought to show it in the way we treat each other.

The “Lean meaning” of respect goes beyond the basics, though.

As a first step, Lean leaders recognize that we totally depend on our people for every aspect of the business. Second, since we depend on them, we need to help them grow and coach them to develop themselves. Third, we need to challenge them. Challenge drives development; it also drives satisfaction. In his research on what brings people to the satisfaction of what he calls the state of “Flow”, psychologist Mihaly Csikszentmihalyi found that people are happiest at work, not on vacation. In his book “Flow: The Psychology of Optimal Experience (1990), he wrote: “The best moments usually occur when a person’s body or mind is stretched to its limits in a voluntary effort to accomplish something difficult and worthwhile. Optimal experience is thus something we make happen. (Csikszentmihalyi, 1990, p.3)

From that, we understand that challenging employees to stretch their skills is probably the most important factor in employees satisfaction and long-term retention.

Leadership is a science and an art. Its main goal is to inspire employees to align their behavior with the philosophy and the goals of the practice. Any of us find dealing with employees difficult at times, especially when we want them to change their behavior. But it doesn’t have to be that way. The lean way of leadership, “Go see, ask why, show respect” can go a long way in making that change not only easy, but also enjoyable.

Dr. Sami Bahri is the author of “Follow the Learner: The Role of a Leader in Creating a Lean Culture,” and of the DVD “Single Patient Flow: Applying Lean Principles to Heathcare”. The book won the 2010 Shingo Prize for Research and Professional Publication and the video won the same award for 2013. The Shingo Prize Conference also recognized Bahri as the “World’s First Lean Dentist.” He is a soughtafter speaker and lecturer nationally and internationally on implementing Lean management in dentistry. Dr. Bahri can be reached at [email protected]